CLOSED-LOOP CONTROL – 21030

Closed-loop control is a form of robot manipulator motion control in which the path, or trajectory, of the device is corrected at frequent intervals.

After motion begins, a position sensor detects possible errors in the trajectory.If an error is detected, the sensor outputs a signal that operates through a feedback circuit to bring the manipulator back on course. The term derives from the fact that the feedback and control-signal circuits together constitute a closed loop.

The main asset of closed-loop control is accuracy. In addition, closed-loop control can compensate for rapid, localized, or unexpected changes in the work environment. The principal disadvantages are greater cost and complexity than simpler schemes such as ballistic control.

CLOSED-LOOP SYSTEM

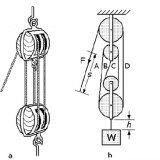

A closed-loop systemis a set of devices that regulates its own behavior.Closed loops can be found in many kinds of machines, from the engine in a car (governor) to the gain control in a radio receiver (automatic level control).

A closed-loop system, also known as a servomechanism, has some means of incorporating mechanical feedback from the output to the input. A sensor at the output end generates a signal that is sent back to the input to regulate the machine behavior. A good example of this is a back pressure sensor. Another example is closed-loop control of a robot manipulator.